Your present location:Home >> Alcohol project >> 60,000T 5column differential pressure fuel alcohol project

- Mob: 0086-13818596142

- liadingdan@163.com

Products Name:60,000T 5column differential pressure fuel alcohol project

Products Number:802

Add Time:2023-02-09 19:08

Views:

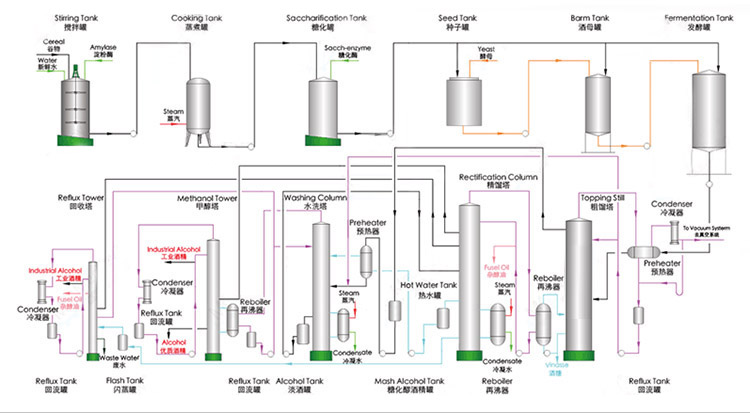

Full-automatic multifunctional alcohol production line for sale can produce food grade alcohol /ethanol ,industrial alcoho and fuel alcohol , food grade alcohol processing line for sale fuel alcohol production line, Fuel ethanol /food grade ethanol complete line for sale, Turnkey project --Industrial ethanol /fuel alcohol plant / food grade ethanol / alcohol equipment , Edible alcohol machine, Five-column Differential-pressure Distillation Plant, 95%-99% purity alcohol /ethanol processing line

Company for alcohol factory of the overall design, technical renovation, alcohol is a full set of production equipment design, manufacture, installation and debugging, benzene method, molecular sieve method and differential pressure distillation, edible alcohol, medical alcohol and ethanol plant design and construction, with complete sets of equipment design and production capacity 3 ~ 300000 tons of alcohol.

Sales Performance

Alcohol DDGS complete equipments are the first choice of clients at home and abroad. The products are used by more than a thousand of clients from over 20 provinces throughout the country and exported successively to above 20 countries such as Argentina, Austrilia, Myanmar, Thailand, Russia, Iran, Mongolia, Kazakhstan and so on, all of which are trusted by new and old clients, being praised as “Pyramid” in China. And we can undertake complete turn-key project of 3000t-500000t alcohol equipments. The following are some projects:

Product Description

Specifications

Alcohol equipment, Differential pressure, fuel ethanol equipment, dehydration alcohol ethanol equipment

Distillation columns

Alcohol equipment , Differential pressure,Fuel ethanol equipment plant,Dehydration alcohol ethanol equipment, Distillation columns,alcohol(ethanol) production line,Turn-key whole set alcohol equipment,fuel ethanol equipment , alcohol distillation equipment

dehydration ethanol equipment

1. It is a turn key whole set equipment, simple equipment, less worker, less area, less cost.

2. Can produce 1000L-1000000L 96%-99.9% alcohol(ethanol) per day.

3. Can use Corn, wheat, cassava, molasses, rice, potato, date, beetroot, sugar cane ect which contains starch or sugar material.

4. We can do the turn key system or section part.

5. Can improve and rebuild old alcohol(ethanol) production line.

You can choose single distill tower to save money, also can choose 5 distill column to get good quality alcohol(ethanol).

DDGS; Distillers Dried Grains with Solubles的简写,汉译为干酒糟及其可溶物。DDGS是酒糟蛋白饲料的商品名,即含有可溶固形物的干酒糟。

We make many kinds alcohol equipments. Medical ethanol ,fuel ethanol and DDGS high protein feed Complete equipment ,medical ethanol in China, being regarded as national high-tech enterprise, star enterprise, standing commissioner of the National Alcohol Association, national demonstration unit of both quality and credibility assurance, national enterprise in designing and manufacturing class-I, class-II, class-III pressure vessel. We are capable to design, manufacture, install and adjust 3000t-500000t alcohol complete equipment on alcohol producing equipment and DDGS complete equipment, winning the National Science & Technology Progress Award many times. We are the first choice of clients at home and abroad. Material of alcohol equipment is corn, tapioca, potato, and other amyloid plants; Sirup, sugarcane, sugary jowar. We can also design for you according to your requirements.

We have a lot of commercial partners in Europe, America and Southeast Asia because of our advanced technology and reliability and reasonable prices.

Alcohol equipment, ethanol equipment, fuel ethanol equipment, dehydration alcohol ethanol equipment

Distillation columns

|

Processing: |

Fermenting Equipment,Distillation, fermenting, liquefaction, saccharification |

Condition: |

New |

Place of Origin: |

Shandong China (Mainland) |

|

Brand Name: |

|

Processing Types: |

Alcohol |

Voltage: |

220V/380V/440V/as your requirement |

| Power(W): |

as your requirement |

Dimension(L*W*H): |

as your requirement |

Weight: |

as your requirement |

|

Certification: |

ASME, ISO,CE |

Warranty: |

24 months |

After-sales Service Provided: |

Engineers available to service machinery overseas |

|

Material: |

Stainless Steel, Carbon Steel, Alloy(Titanium) Etc. |

Application Industries: |

Alcohol Plant, Fuel Ethanol, Petrochemical Engineering, Starch Etc. |

OEM: |

available |

Product Description

Quick Details

Packaging & Delivery

|

Packaging Detail: |

Export standard seaworthy |

| Delivery Detail: | 35-120days |

Specifications

95%-99.9% Alcohol/ethanol distillation equipment

DDGS dryer machine

Fermenting

ASME, ISO, CE

Produce as your requirement

Alcohol equipment, Differential pressure, fuel ethanol equipment, dehydration alcohol/ethanol equipment, distillation columns

Spiral plate Heat exchanger, Shell and tube heat exchanger, Condenser, Reboiler, Preheater, Evaperator, Dryer machinery

Our Services

1:Before Service: All the processes of alcohol/fuel ethanol production line are specially designed by Technical deportment according to each customer’s requirements and we have Strict Quality Control System of all the alcohol/ fuel ethanol equipment.

2:Middle Service: Supply engineers and workers training during the installation and debugging of the alcohol/fuel ethanol plant. If any question, pls feel free to contact us for solution.

3:After-sale Service:Supply lifetime technology consultation and advice of the alcohol/fuel ethanol production plant. If you have any problem or question about the alcohol distillery/bio ethanol plant, pls call us and E- mail us at any time, we will reply to you at the shortest time. Engineers are available to go to plant site to help customers to improve processes or technology if required.